Ask For A Quick Quote

We will contact you within 1 working day, please pay attention to the email with the suffix “@fsdym.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@fsdym.com”.

Lean production is a management philosophy aimed at optimizing the production process by eliminating waste, improving efficiency and quality, and better meeting customer needs.

The following are the main benefits of lean production:

Reduce costs. By eliminating waste in the production process.Reducing inventory, reducing scrap rates, and optimizing resource allocation, lean production can help enterprises significantly reduce production costs. Improve product quality.

Through process optimization and standardization, lean production can reduce error rates and deviations in product manufacturing, thereby improving product consistency and quality.

Improve production efficiency. By eliminating bottlenecks and waste in the production process, as well as real-time monitoring and data analysis, lean production can improve production efficiency and reduce downtime. Improve employee engagement and satisfaction.

By involving employees in the improvement process, lean production can enhance their skills and satisfaction, while providing them with better work ,environment and career development opportunities.

Optimize processes and overall benefits. Lean production improves the overall efficiency of the enterprise by improving processes and establishing an uninterrupted process to quickly respond to customer needs.

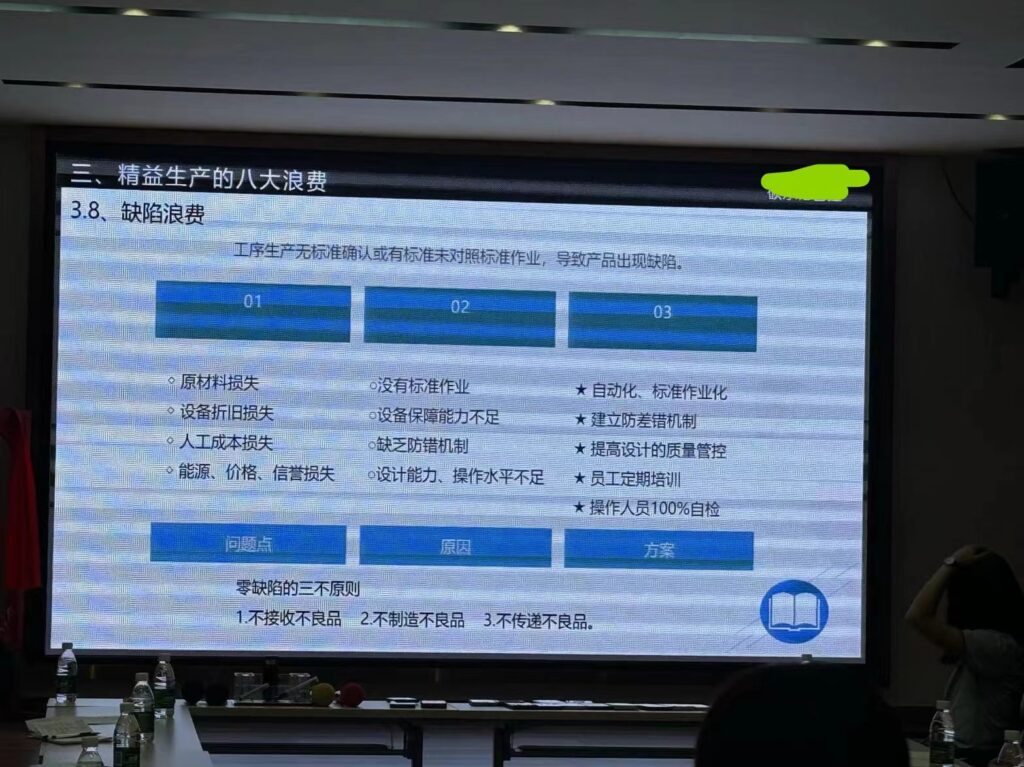

Eliminate the eight major wastes. Lean production helps businesses fundamentally eliminate waste, including overproduction, waiting time, transportation, inventory, processes (processes), actions, product defects, and neglecting employee creativity.

High quality and one-time qualification throughout the entire process. By internalizing quality in design, process, and manufacturing, lean production requires achieving high quality throughout the entire process, making it right at once.

Pull based production based on customer needs. Lean production emphasizes producing according to customer needs, reducing losses caused by early or late production.

In addition, lean production can help improve service quality, save ordering costs, save job exchange costs, and increase the utilization of personnel and equipment. By implementing lean production, enterprises can reduce costs without sacrificing quality, while maintaining stable and improved product quality.

DYM trains on lean production and strives to become the preferred brand for dentists, making customers more at ease.