Ask For A Quick Quote

We will contact you within 1 working day, please pay attention to the email with the suffix “@fsdym.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@fsdym.com”.

Dental handpiece lubricant devices are key equipment used to maintain dental handpieces in dental clinics. By cleaning, lubricating, and maintaining the precision components within the handpiece, they ensure sterilization, extend the lifespan, and guarantee safe treatment. DYM Medical, a professional manufacturer of dental handpiece lubricant devices, will share with you the key aspects of dental handpiece lubricant devices, including technical principles, classification comparisons, operating procedures, market status, and purchasing considerations. Why should dental clinics use this type of dental handpiece lubricant devices? https://fsdym.com/product/white-color-digital-screen-dental-2-hole-handpiece-lubricator/

1. Technical Principles and Core Functions of Dental Handpiece Lubricant Devices

Dental handpieces have complex internal structures. Components such as bearings, impellers, and pressure shafts are susceptible to wear due to insufficient lubrication during high speed operation (20,000-30,000 rpm for low speed handpieces and up to 400,000 rpm for high speed handpieces), requiring regular lubrication and maintenance. The core function of the DYM dental handpiece lubricant devices is to provide maintenance through the following process:

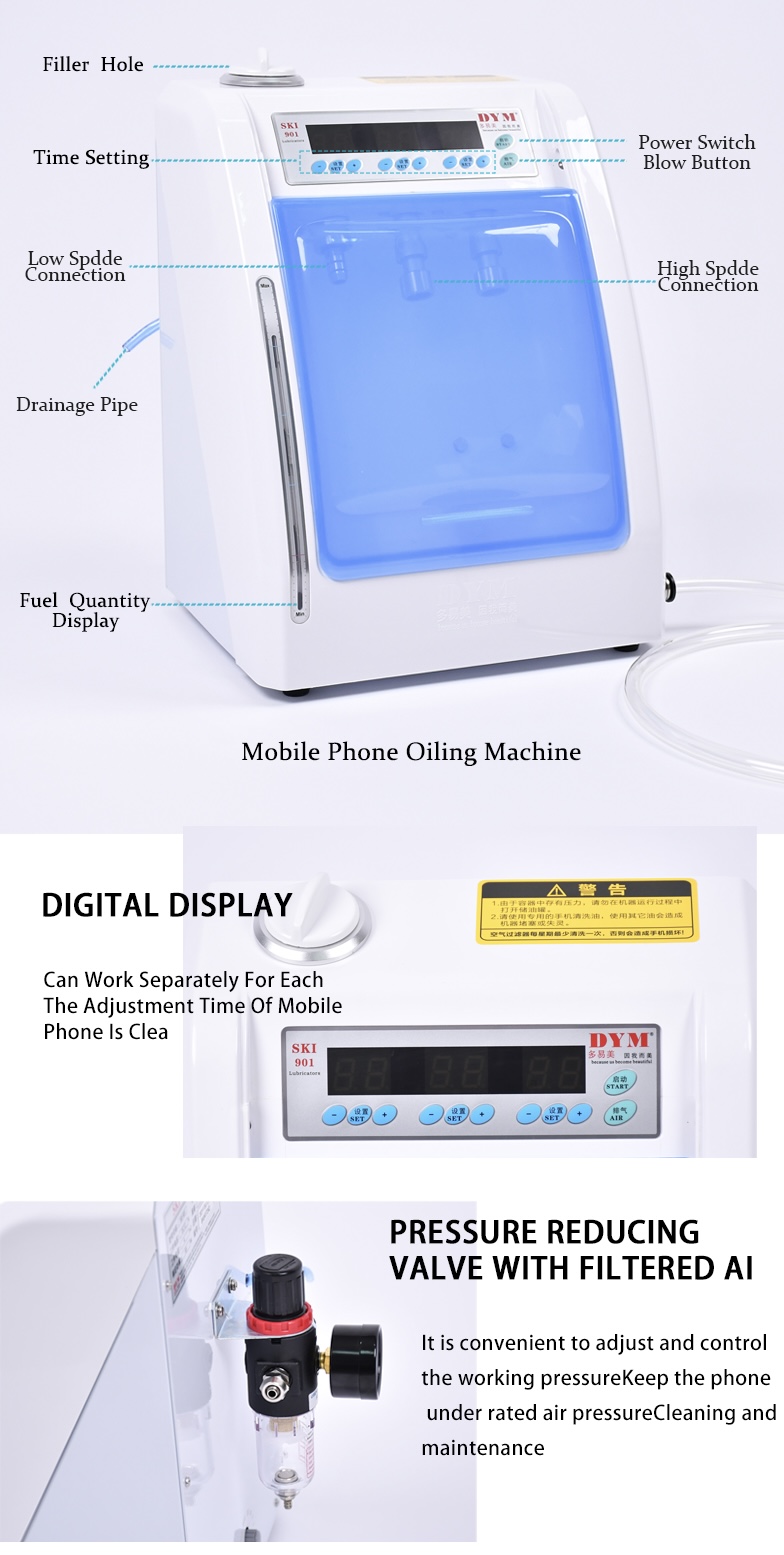

Precise Oiling: Air pressure is used to inject the specialized DYM SKI lubricant into the internal channels of the dental handpiece, injecting approximately 0.2-0.5 ml of oil per operation. Deep oiling is performed for approximately 5 seconds, followed by chip removal and other maintenance procedures.

Keep Dry after Air Blowing: After oiling, purge with compressed air (usually for 4-5 seconds) to remove excess oil and prevent solidification and carbonization of the oil during high temperature sterilization.

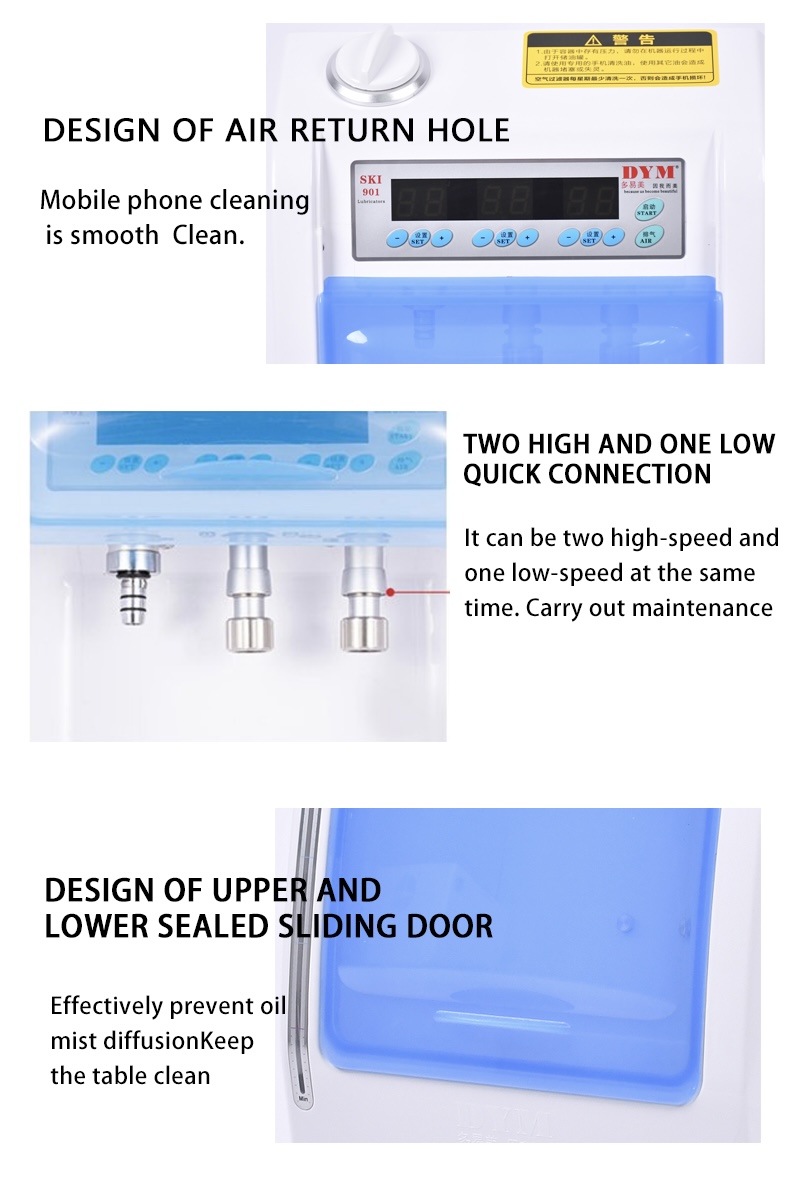

Research has shown that automated oiling with a dental handpiece lubricant device is more effective than manual operation, saving time and effort while providing a more thorough cleaning. This reduces residual impurities in the dental handpiece’s channels and extends their lifespan. DYM provides one-stop supporting services for dental equipment. Its SKI-901 dental handpiece lubricant device is equipped with two stainless steel high speed handpiece quick connectors and one stainless steel low speed handpiece connector. Dental handpiece lubricant can achieve efficient replacement of handpiece connectors, saying goodbye to the threaded connector design of traditional handpiece lubricant devices. The repetitive actions of plugging and unplugging and tightening waste a lot of work time of dentists, thereby reducing the waiting time of oral patients.

2. Dental Handpiece Lubricant Device Advantages and Technical Parameters

3. Operation Procedures and Precautions of Dental Handpiece Lubricant Devices

4. Key Points for Purchasing and Maintaining Dental Handpiece Lubricant Devices

DYM offers a 1-year or longer warranty on its SKI-901 dental handpiece lubricant device, along with lifetime repair assistance. We also provide 1-3 free technical inspections annually. With the advancement of standardization in dental care, handpiece lubricant devices have become a cornerstone of infection control. Their standardized use directly impacts both medical safety and the operating costs of dental institutions, worthy of our partners’ close attention.

DYM is committed to becoming a trusted dental equipment brand for dentists worldwide.