Ask For A Quick Quote

We will contact you within 1 working day, please pay attention to the email with the suffix “@fsdym.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@fsdym.com”.

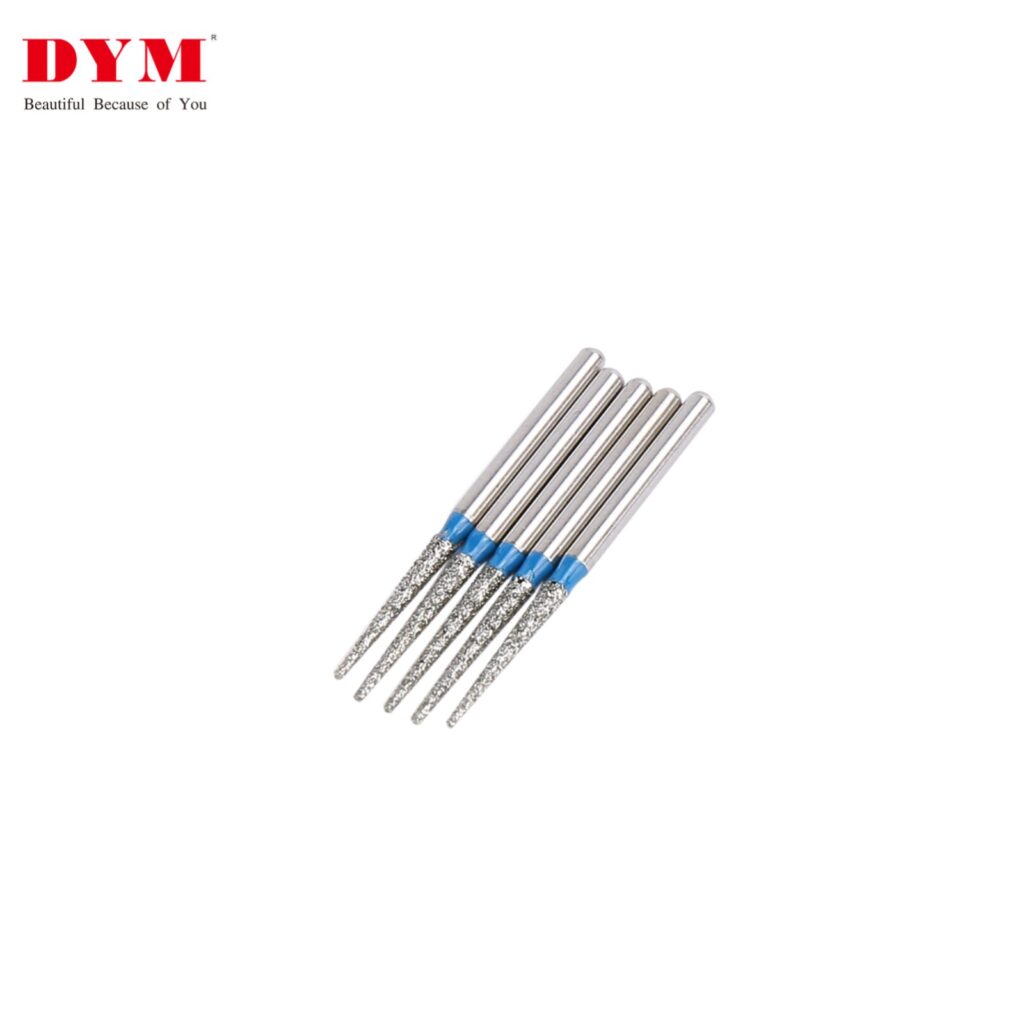

Dental burs, also known as high-speed diamond burs, are essential rotary cutting tools commonly used in dental procedures. They are mounted on dental handpieces (high-speed or low-speed) and serve purposes such as cutting, grinding, and shaping teeth or restorations. Made in various materials, shapes, sizes, and designs, they are suitable for a wide range of clinical applications.

Specifications:

Standard length: 19mm

Shank diameter: 1.6mm

Material: High-grade stainless steel (316 or 402)

Surface treatment: Nickel-plated with diamond grit coating for sharpness and wear resistance

Variety: Over 110 commonly used shapes to suit different dental procedures and dentists’ preferences

Main Applications of Dental Burs:

Diamond burs: For cutting hard tissues like enamel; highly efficient.

Tungsten carbide burs: For fine-tuning cavity margins or removing soft caries.

Available in various shapes (round, tapered, flat, pointed) to suit cavity types (e.g., Class I or Class II).

Metal restorations: Diamond burs for polishing metal surfaces.

All-ceramic restorations: Fine-grit diamond or ceramic burs to prevent micro-cracks.

Resin restorations: Tungsten carbide or polishing burs for precise adjustments.

Tapered diamond burs: For shoulder preparation (e.g., chamfer, shoulder).

Cylindrical burs: For axial reduction and ensuring sufficient space for restorations.

End-cutting burs: For finishing margins, including interproximal and subgingival areas.

Pulp chamber access: Round or long-shank burs to open the pulp chamber.

Canal orifice shaping: Tapered burs for refining root canal entrances.

Removing calcification: Long-neck, fine-point burs to clear obstructions.

Infection Control:

Dental burs must be properly disinfected to prevent cross-contamination, as they come into contact with saliva, blood, and debris.

Recommended disinfection procedure:

Soak in 2% glutaraldehyde solution for 30 minutes

Clean thoroughly with a fine-bristled brush to remove debris in the texture

Rinse with water, dry, and package for reuse

About DYM – Duo Yimei Medical Instrument Co., Ltd.

With over 18 years of experience in dental bur manufacturing, Duo Yimei (DYM) proudly presents the SKI brand of high-speed diamond burs.

Monthly production capacity: 2 million pieces

Global reach: Exported to South America, Central Asia, Southeast Asia, the Middle East, and many domestic cities in China

Production lines: 30 fully equipped dental bur production lines

Packaging: Standard 5-piece blister packs, 50 pieces per box (custom packaging available)

Why Choose SKI Burs?

Sharp and durable

Consistent quality with every piece inspected by our advanced visual inspection systems

Fast delivery cycles thanks to efficient production and inventory management

We welcome dental equipment distributors and consumable agents worldwide to collaborate with us. Let’s grow together in the dental industry.