Ask For A Quick Quote

We will contact you within 1 working day, please pay attention to the email with the suffix “@fsdym.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@fsdym.com”.

In modern dental clinics, the dental chair is one of the crucial pieces of equipment. It not only provides a comfortable environment for patients but also supports dentists in performing complex treatment procedures. The production of dental chairs requires careful selection of materials, rational design of structure, and strict quality control. This article will explore the production process of dental chairs from these aspects, accompanied by detailed diagrams.

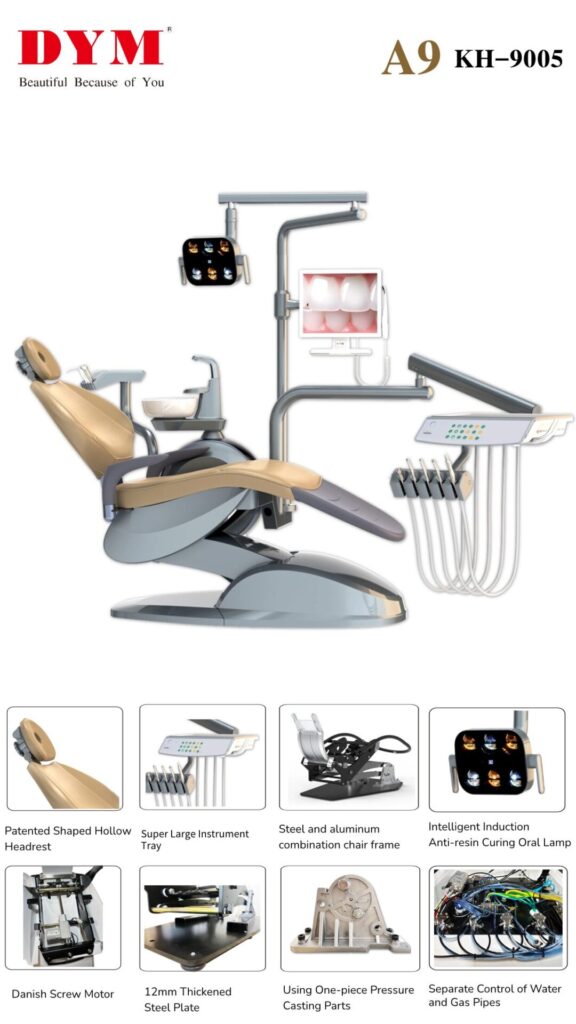

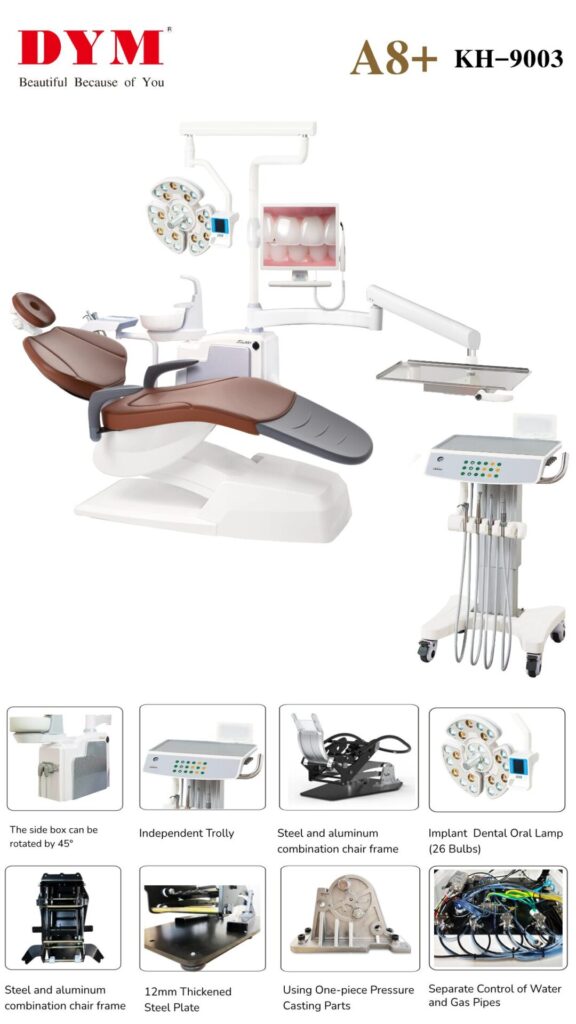

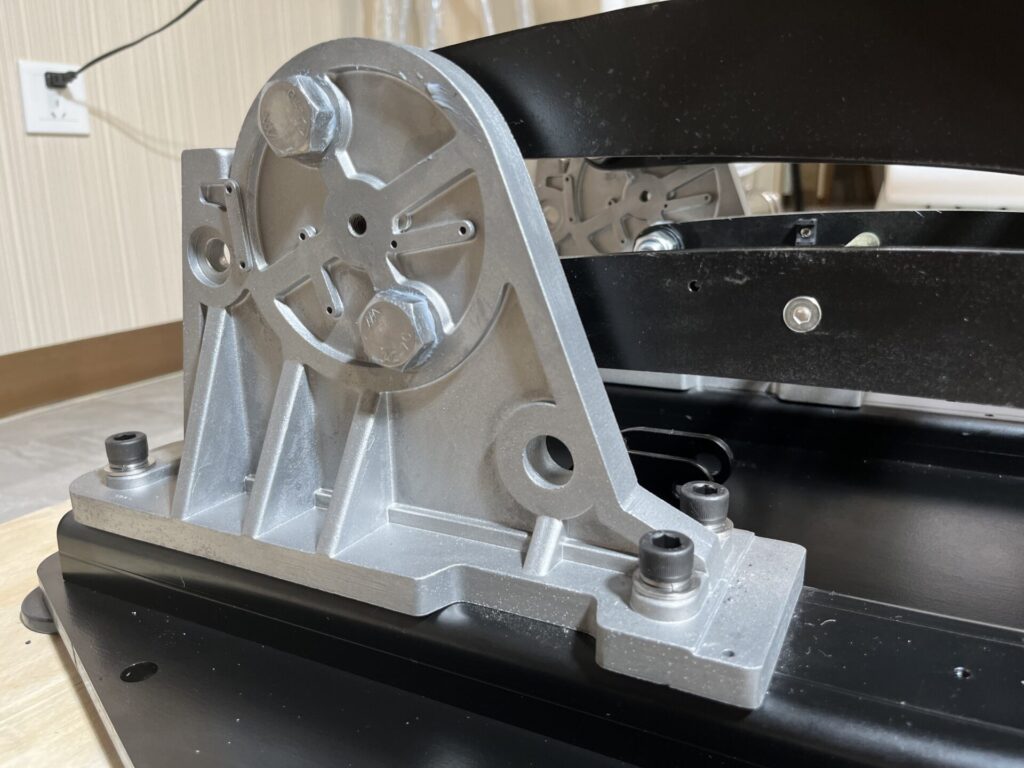

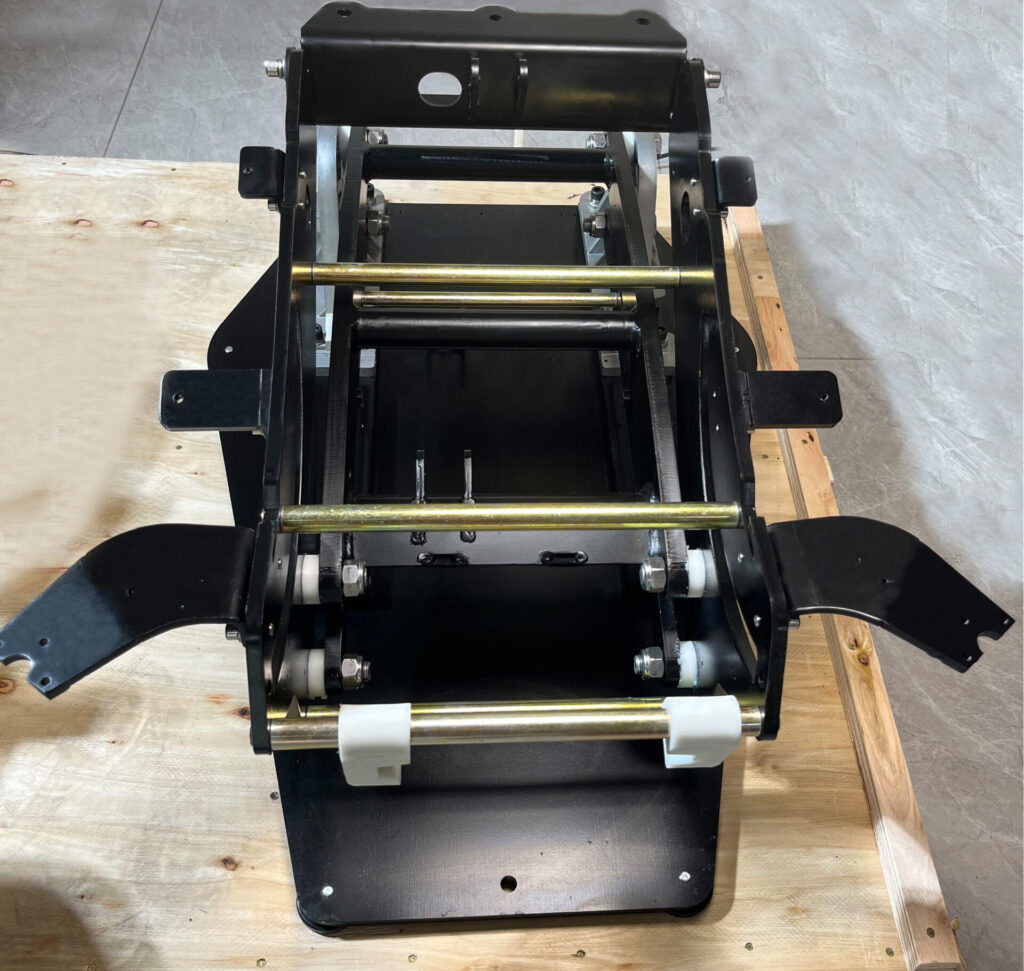

The main materials for dental chairs typically include metal, plastic, and leather. The metal parts are usually made of high-strength stainless steel or aluminum alloy to ensure the stability and durability of the dental chair. Plastic parts need to possess sufficient toughness and abrasion resistance to withstand various pressures and friction in daily use. Meanwhile, the seating and backrest of the dental chair are often made of high-quality leather or faux leather materials, ensuring both comfort and easy cleaning.

The structural design of dental chairs directly affects their stability and comfort. Generally, a dental chair consists of a base, armrests, seat, backrest, headrest, and other components. The base typically adopts a cross-shaped design to increase stability and support, while equipped with casters for easy movement. The height and angle of the armrests and backrest are adjustable to accommodate the needs of different patients. The padding of the seat and backrest should have sufficient elasticity and support to ensure that patients do not feel fatigued even after prolonged sitting.

Quality control is crucial throughout the production process of dental chairs. From material procurement to manufacturing, and finally to the final inspection and packaging, every step requires strict control. For metal parts, surface treatment is necessary to prevent oxidation and corrosion; for plastic parts, precise dimensions and smooth surfaces that are not easily deformed are ensured. During assembly, it is essential to strictly follow the design requirements to ensure that each component is firmly and stably connected. The final quality inspection process involves comprehensive testing of each dental chair to ensure its proper functioning, flawless appearance, and is accompanied by detailed user manuals and after-sales service guarantees.

Through meticulous control of materials, structure, and quality, the produced dental chairs not only have excellent stability and comfort but also meet the needs of different patients, providing dentists with a good working environment and patients with a high-quality treatment experience.